Pre-milling For Edgebanders

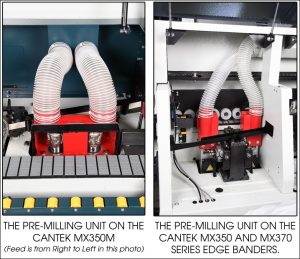

More often today you are finding features on smaller edge banders that initially were exclusive to larger, higher production machines. One of those features is pre-milling. Pre-milling consists of two counter-rotating cutterheads which are designed to mill the edge of the panel prior to applying the edge banding material.

The cutterheads are set up to mill a specific amount of material and remove any imperfections or chipping left from the saw or router during the cutting process. For example, if your scoring blade is not perfectly set. As tooling gets dull on your panel saw or CNC router the edge quality deteriorates. Sometimes imperfections are left on the surface or within the substrate. The pre-milling cutterheads produce the optimum edge by ensuring the edge is perfectly square. This helps significantly in minimizing the visible glue joint which with today’s wide range of materials including high gloss panels is certainly a necessity.

The cutterheads are set up to mill a specific amount of material and remove any imperfections or chipping left from the saw or router during the cutting process. For example, if your scoring blade is not perfectly set. As tooling gets dull on your panel saw or CNC router the edge quality deteriorates. Sometimes imperfections are left on the surface or within the substrate. The pre-milling cutterheads produce the optimum edge by ensuring the edge is perfectly square. This helps significantly in minimizing the visible glue joint which with today’s wide range of materials including high gloss panels is certainly a necessity.

The heads are diamond coated which will stay sharp longer and provide for a long life. The cutting segments are set on a shear angle so that they are angled up from the bottom and down from the top to ensure optimum finish on laminated surfaces. The heads are counter rotating with the first cutterhead machining the start of the panel by climb cutting, the second head will then pneumatically jump in the machine the tail edge of the panel with a climb cutting rotation. By climb cutting the panel you are eliminating any possible tear out. The fence can be set to remove a specific material amount typically matching the thickness of the edgebanding you are going to apply. This way your finished panel dimension will not change. This helps to ease the operations of the panel saw or router so that the panel size does not need to be compensated for.

The heads are diamond coated which will stay sharp longer and provide for a long life. The cutting segments are set on a shear angle so that they are angled up from the bottom and down from the top to ensure optimum finish on laminated surfaces. The heads are counter rotating with the first cutterhead machining the start of the panel by climb cutting, the second head will then pneumatically jump in the machine the tail edge of the panel with a climb cutting rotation. By climb cutting the panel you are eliminating any possible tear out. The fence can be set to remove a specific material amount typically matching the thickness of the edgebanding you are going to apply. This way your finished panel dimension will not change. This helps to ease the operations of the panel saw or router so that the panel size does not need to be compensated for.

Contact us to find out more about our Edgebanders with Pre-milling!

|

|

|

|

| Cantek MX350 | Cantek MX350M | Cantek MX370A | Bi-Matic Prima Plus Series |